Environmental Initiatives

- *1 Emissions associated with in-house fuel consumption

- *2 Emissions associated with in-house power usage

The MEDIPAL Group is mainly engaged in the wholesale business in the pharmaceuticals, health and beauty fields, and contributing to build a sustainable society through its business activities. As a company responsible for distribution, we consider reducing greenhouse gas emissions to be a pressing issue. We are working to optimize the entire supply chain and are progressing with initiatives to reduce the environmental impact of our operations and achieve the Sustainable Development Goals (SDGs).

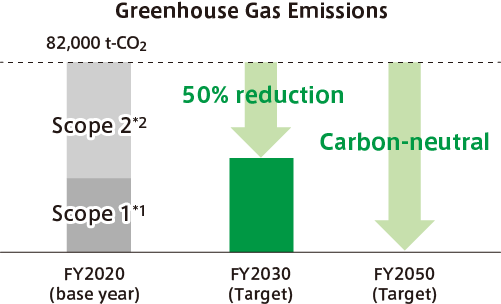

When implementing these environmental initiatives, we have defined Initiatives for Decarbonization as one of our Material Sustainability Tasks (Materiality), and have set medium- to long-term targets of a 50% reduction in greenhouse gas emissions by FY2030 (versus FY2020 levels) and carbon neutrality by FY2050. To achieve these targets, we are implementing a number of different initiatives with the goal of building an environmentally friendly distribution model.

In addition, in recent years, companies have been asked to consider biodiversity as a corporate environmental initiative. In the MEDIPAL Group, we believe that we have limited dependence and impact on biodiversity at the present. We will continue to analyze the connections between our businesses and biodiversity, and endeavor to provide appropriate disclosure, according to the circumstances.

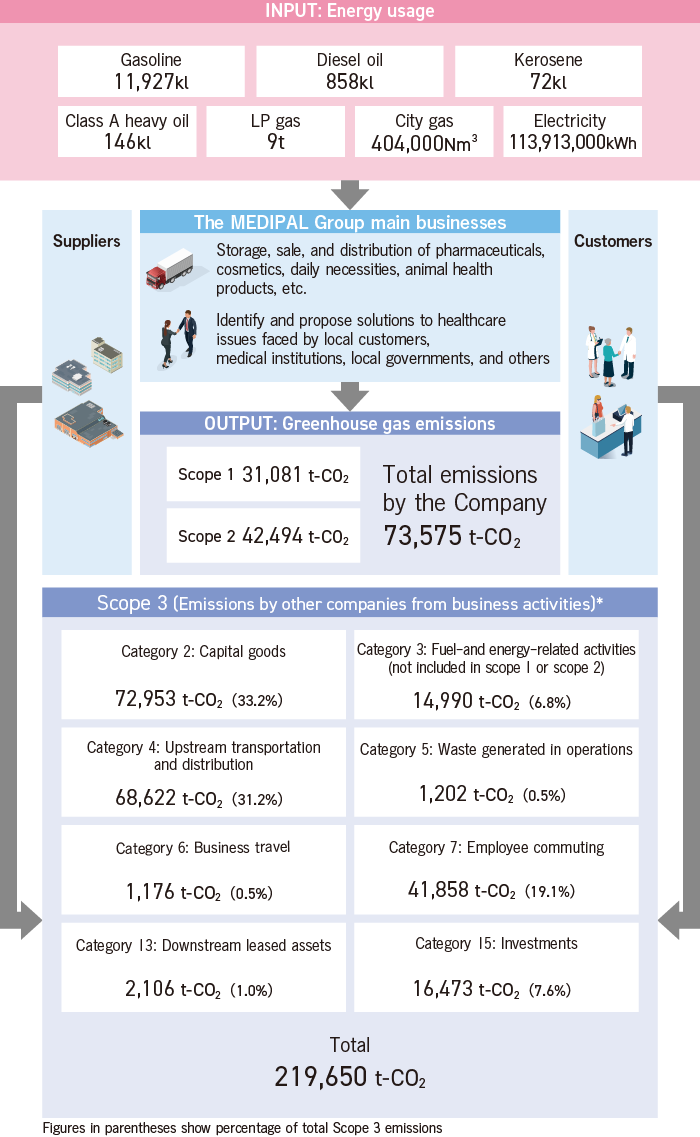

Environment Burden from the Supply Chain (FY2024)

- Implemented at the Company and its consolidated subsidiaries

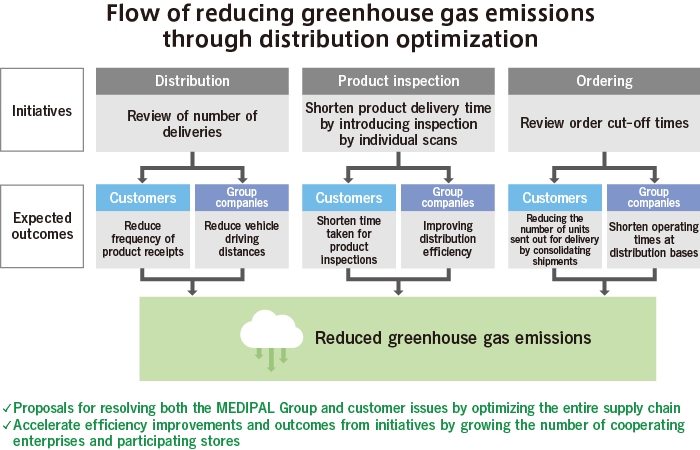

Optimizing pharmaceutical distribution

In our Prescription Pharmaceutical Wholesale Business, we are collaborating with our customers, including drugstore and dispensing pharmacy chains, to build an optimized pharmaceutical distribution model that reduces greenhouse gas emissions.

Specific measures include analyzing and managing the optimal inventory of pharmaceuticals for each store as well as streamlining operations such as ordering, delivery, and product inspection.

This lightens the delivery workload and enhances operational efficiency while reducing greenhouse gas emissions accompanying distribution.

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.

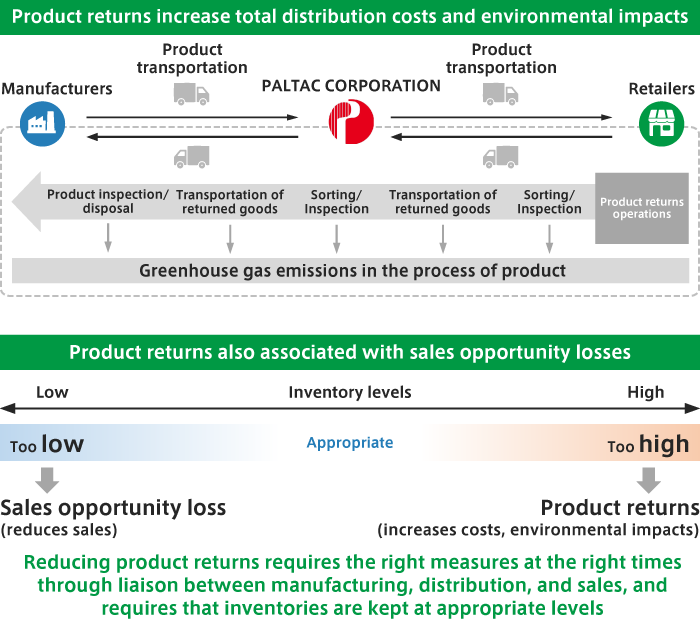

Reducing product returns

PALTAC CORPORATION is working with business partners to reduce product returns towards build a more sustainable distribution cycle.

Product returns are standard commercial practice in the cosmetics, daily necessities, and OTC pharmaceuticals industry.

As well as generating additional costs for product sorting and delivery, product returns increase environmental impacts through greenhouse gas emissions and product waste. Returns occur during the process of quickly introducing products to stores in response to Japan’s four seasons and changing consumer needs, and are inextricably linked to lost sales opportunities. We must maintain appropriate inventory levels by coordinating right across the supply chain, creating sales spaces that satisfy consumer needs (and do not result in sales opportunity losses) and reducing product returns.

PALTAC CORPORATION is working to reduce product returns by liaising with retailers and manufacturers from the early stages, to assess store sales and inventory levels, movements in sales indicators for seasonal products as temperatures change, as well as information on upgraded or discontinued products, and to implement the right solutions at the right time, including preventing excess inventory levels by transferring stock between stores or putting a stop on order placement.

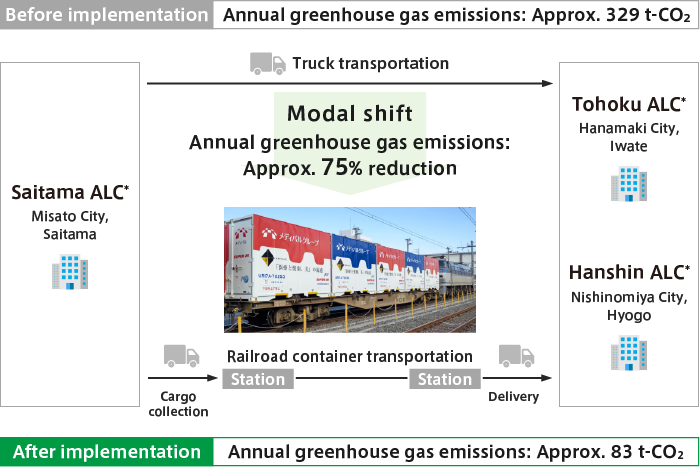

Modal shift

MEDICEO CORPORATION, Japan Oil Transportation Co., Ltd., Japan Freight Railway Company, and Japan Freight Liner Company are working on a joint project to achieve a modal shift* in pharmaceutical transportation between distribution centers.

The project promotes the switching of product transportation in some areas away from conventional use of large trucks toward more environmentally friendly railroad containers, to reduce greenhouse gas emissions. From April 2025 we started a new modal shift for transportation from the Tokyo metropolitan area to Hokkaido. Calculated annually, these initiatives are expected to reduce greenhouse gas emissions by approximately 71% and 446 t-CO2 compared to conventional transportation.

* The shift of transportation of goods from trucks and other motor vehicles to modes with lower environmental impact such as railways and ships.

Project awards

- Received the Low Carbon Logistics Award at the 22nd Logistics Environment Awards

- Received the 20th Green Logistics Partnership Conference Special Award in FY2021

- Received the Special Award at the 24th Logistics Environment Awards

Schematic of modal shift

(between the Saitama ALC and Tohoku ALC・Hanshin ALC)

* ALC: Area Logistics Center

A state of art distribution center that supplies prescription pharmaceuticals, medical materials and clinical diagnostic reagents, etc., primarily to dispensing pharmacies, hospitals and clinics.

Introduction of EVs and Hybrid Vehicles

We are making progress on gradually switching to Electric vehicles and hybrid vehicles at each location as we work to reduce greenhouse gas emissions from fuel consumption in our Company.

We have also made Electric vehicles charging stations available to visiting manufacturers at some locations, and this is contributing to promotion of Electric vehicles use by our business partners.

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- Toshichi Inc.,

- MM CORPORATION,

- ASTEC Co., Ltd.,

- MEDISKET CORPORATION,

- PALTAC CORPORATION,

- MP AGRO CO., LTD.,

- MP Gokyo Food & Chemical Co., Ltd.

Environmentally friendly product development

One of PALTAC's new initiatives to increase ethical consumption is to develop environmentally friendly products that use waste plastic as raw materials, through collaboration with companies that develop products and materials to facilitate resource circulation. As well as products from other manufacturers, PALTAC is developing its own products with the goal of actively contributing to the distribution of more high-value-added products that allow consumers to appreciate how they are helping the environment.

Garbage bags: The more you use, the less plastic waste in the world

Joint development with TBM Co., Ltd.

- Recycled materials

- Eco-mark certified

- Use of these garbage bags instead of bags made from virgin plastic reduces plastic waste volumes

Sustainabrella: An umbrella that will not add to landfills

Joint development with

TBM Co., Ltd. and Ca et la Co., Ltd.

- Recycled materials

- Safe, flat design for the ferrule at the umbrella tip

- Long-lasting umbrella that can withstand windy conditions and does not rust

- Recyclable because of all-plastic design

- Umbrella ribs made from strong plastic

- High durability

Use of Eco-Friendly Electric Power

The MEDIPAL Group have introduced renewable energy inhouse power generation facilities, such as rooftop solar panels, in some Group buildings. The power generated is used in the buildings and covers part of the total electricity used, thereby reducing greenhouse gas emissions. We introduced them at two more locations in FY2024, to bring the number of locations where they are operating up to three. In addition, at 36 buildings across the MEDIPAL Group, we have switched to eco-friendly electric power, which together with procurement of non-fossil certificates is helping to reduce greenhouse gas emissions from electric power use.

- MEDIPAL HOLDINGS CORPORATION,

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- MM CORPORATION,ASTEC Co., Ltd.,

- PALTAC CORPORATION,

- MP AGRO CO., LTD.,

- MP Gokyo Food & Chemical Co., Ltd.

Reusable delivery boxes

The MEDIPAL Group uses collapsible plastic containers and tote boxes that can be reused multiple times for product transportation, thus reducing waste volumes and contributing to emissions reductions.

Collapsible plastic containers

A tote box

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- TOSHICHI CO., LTD.,

- MM CORPORATION,

- ASTEC Co., Ltd.,

- PALTAC CORPORATION,

- MP AGRO CO., LTD.

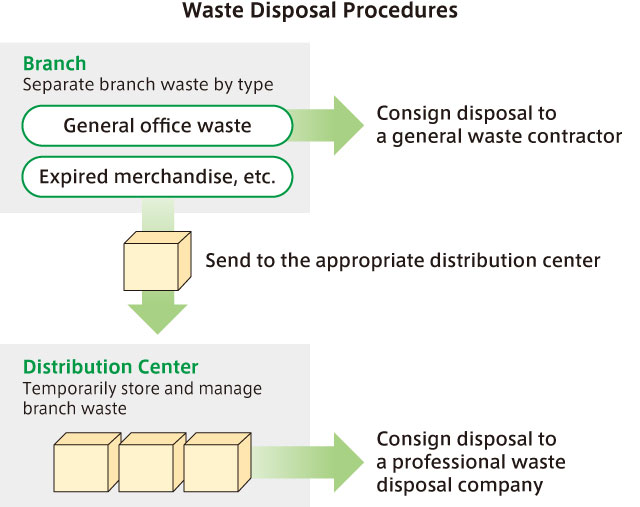

Proper Waste Disposal Manual

The MEDIPAL Group actively promotes reduction and proper disposal of waste in accordance with relevant laws, including the Basic Law for Promoting the Creation of a Recycling-Oriented Society.

We have produced a manual on proper waste disposal, which contains information on waste disposal procedures with a focus on pharmaceuticals. Based on this manual, we dispose of waste appropriately, in accordance with law.

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- TOSHICHI CO., LTD.,

- MM CORPORATION,

- MEDISKET CORPORATION,

- PALTAC CORPORATION

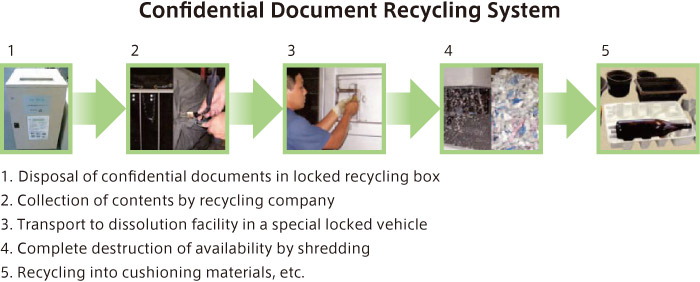

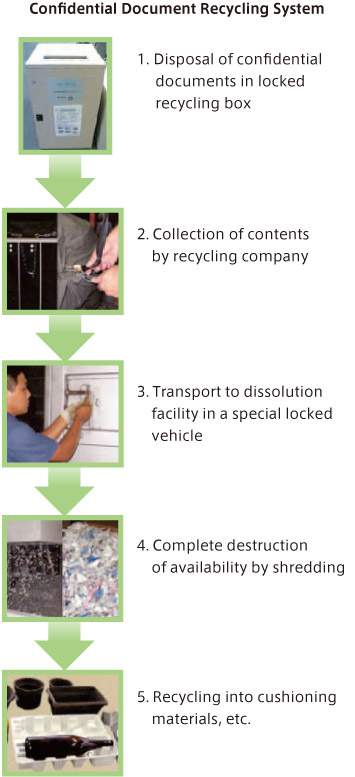

Introduction of a Recycling System for Confidential Documents

We are reducing the use of shredders and introducing a confidential document recycling system (locked recycling box) to facilitate recycled paper recycling. Confidential documents disposed of in these boxes are recycled by a professional contractor into cushioning and other materials.

Recycling Compacted Cardboard

At the MEDIPAL Group's main distribution centers (ALCs and RDCs*), the cardboard boxes left over in large volumes each day are turned into compacted cardboard in a crusher. (The process from compaction to baling and discharge is automated.)

After being compacted into a cube, the cardboard is collected by waste paper companies for recycling as toilet paper and other products.

PALTAC CORPORATION's RDC Sakai

* RDC: Regional Distribution Center

Large-scale distribution centers that handle cosmetics, daily necessities, over-the-counter pharmaceuticals and other items. They supply products to retailers.

- MEDICEO CORPORATION,

- ATOL CO., LTD.,

- PALTAC CORPORATION

Introduction of eco-friendly stretch film for pallet wrapping

The stretch film used for pallet wrapping to prevent load collapse during transportation emits greenhouse gases during both production and incineration. In response to this issue, MEDICEO CORPORATION is using environmentally friendly stretch film made from recycled materials at selected distribution centers.

At Saitama ALC, we have also introduced a new system for collecting and reusing used stretch film generated within the warehouse rather than disposing of it through incineration.

This initiative is expected to reduce greenhouse gas emissions from incineration by approximately 3t-CO2 per year. We will continue to strengthen our efforts to contribute to the realization of a circular, resource-efficient society that is mindful of the global environment.