Quality Control

Basic Policy

The MEDIPAL Group considers it its social mission to comply with pharmaceutical laws and regulations such as the Pharmaceutical and Medical Device Act, and to distribute safe, reliable prescription pharmaceuticals and medical equipment, etc. To accomplish this mission, we strive to implement thorough quality control processes, from pharmaceutical product receipt to delivery to medical institutions, etc., to maintain the integrity of delivered products.

Quality Control Systems

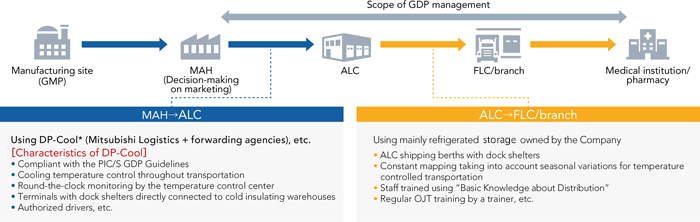

At MEDIPAL Group, our Corporate Reliability Department supervises the status of logistics quality control at four prescription pharmaceutical wholesalers and is working to promote methodologies based on GDP guidelines* at ALCs and to continuously improve the quality of logistics. The department is also working to outfit FLCs and branches throughout Japan with organizational systems based on the guidelines and the necessary capital investments, while implementing educational activities for employees responsible for product management and distribution. In addition, to increase reliability in logistics quality, we are further enhancing our pharmaceutical distribution practices by strengthening cooperation, not only with relevant internal departments but also with pharmaceutical companies, distributors, and other external partners.

* GDP (Good Distribution Practice) guidelines set out appropriate procedures for ensuring the proper management of distribution (purchase, storage, and supply), maintaining the integrity of pharmaceuticals, and preventing the entry of counterfeit drugs into regular distribution channels.

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- SPLine Corporation

Maintaining Quality

For quality control in the storage and distribution of pharmaceuticals, medical equipment, and other products, the MEDIPAL Group ensures the operation of appropriate systems by creating manuals on logistics operations, supervising pharmacist operations, etc., based on ordinances issued by the Ministry of Health, Labour and Welfare, and on JGSP*1 and JGSP2008. The Group also formulates manuals for quality control and standard operating procedures (SOPs) in accordance with the globally harmonized JGSP GDP, revised to reflect PIC/S*2 GDP, and with GDP guidelines issued by the Ministry of Health, Labour and Welfare. In addition, the Group works to enhance management systems, provide opportunities for suggesting improvements at GDP review meetings, and implement educational activities.

The Group is now providing training on quality control manuals and SOPs to the logistics departments of the four prescription pharmaceutical wholesalers as well as to all ALCs. In addition, we carry out regular quality reviews to promote and enhance the quality of GDP activities. In 2022, we also began offering our GDP programs, which had previously focused on centers, at FLCs* and branches, established GDP at EVERLTH Co., Ltd. and ATOL CO., LTD. in FY2023, and are progressively rolling out the programs to Group wholesalers.

*1 JGSP (Japanese Good Supplying Practice: Practices regarding quality control and safety management in the supply of pharmaceuticals): Industry practices defined by The Federation of Japan Pharmaceutical Wholesalers Association in order to protect the safety of products and prevent their degradation due to temperature, humidity, sunlight, etc., during storage, shipping, and transport. JGSP applies to prescription pharmaceuticals, while JGSP2008 applies to over-the-counter pharmaceuticals.

*2 PIC/S (Pharmaceutical Inspection Convention and Pharmaceutical Inspection Co-operation Scheme)

* DP-Cool: Refrigerated transportation service for pharmaceuticals compliant with the PIC/S GDP guidelines

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- SPLine Corporation

Education System

The MEDIPAL Group offers ongoing training for employees engaged in product management and distribution using quality manuals and SOPs to maintain the integrity of pharmaceuticals and other products.

- MEDICEO CORPORATION,

- EVERLTH Co., Ltd.,

- ATOL CO., LTD.,

- SPLine Corporation